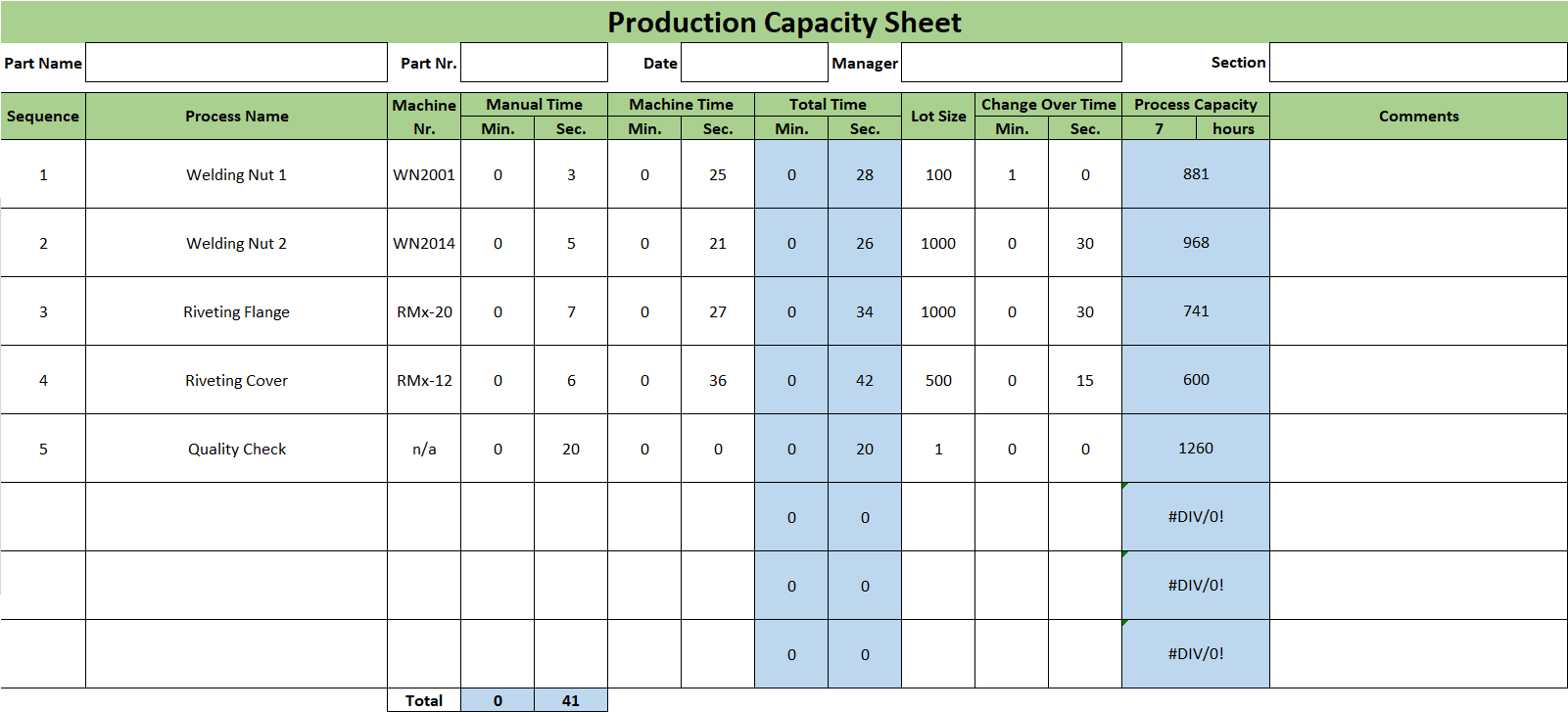

Production Capacity Sheet Header

Manufacturing production capacity is the number of items your employees can produce in a specific period of time, like an hour, day or week. The production capacity is the limit at which employees can manufacture products using the resources available to them, including equipment, materials and hours in their workday.

What Is Production Capacity and How to Calculate It? MTDMFG

How Do You Measure Production Capacity? There are many ways to look at production capacity in your business. In planning for sales growth you need to consider "demonstrated capacity". That is the actual rate of output that has been achieved in recent history, allowing for inefficiency.

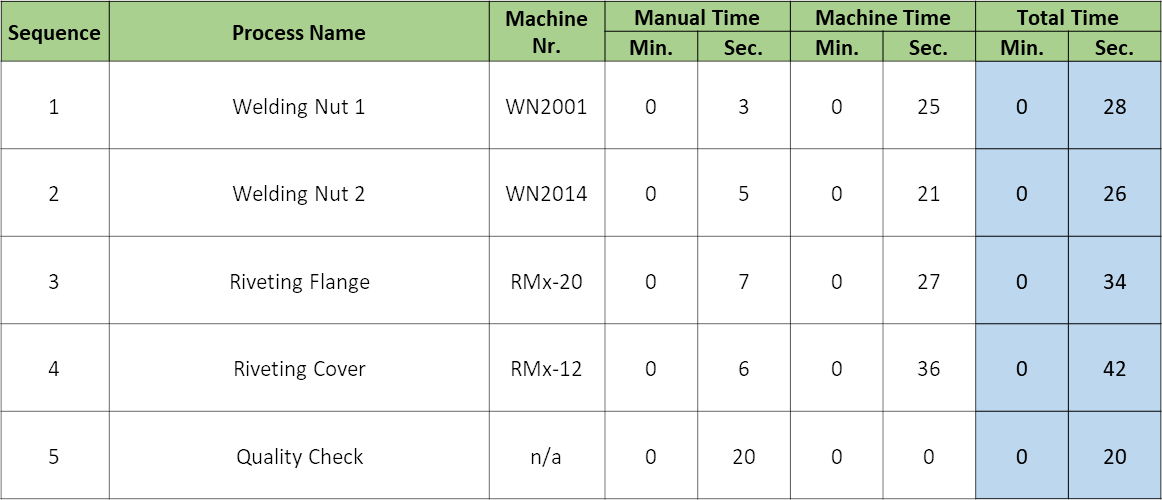

Production Capacity Sheet co times

It is a measure of a company's ability to produce and deliver its products or services and is usually expressed in terms of the number of units produced per unit of time, such as per day, per week, or per month.

How to Increase Manufacturing Production Capacity Machinemetrics

1. Map out the steps in your production process. 2. Determine the Cycle Time for Each Unit. 3. Calculate the Machine-Hour Capacity. 4. Use the Production Capacity Formula. Using these computations, manufacturers determine their production capacities and strategize on how to increase it for efficiency.

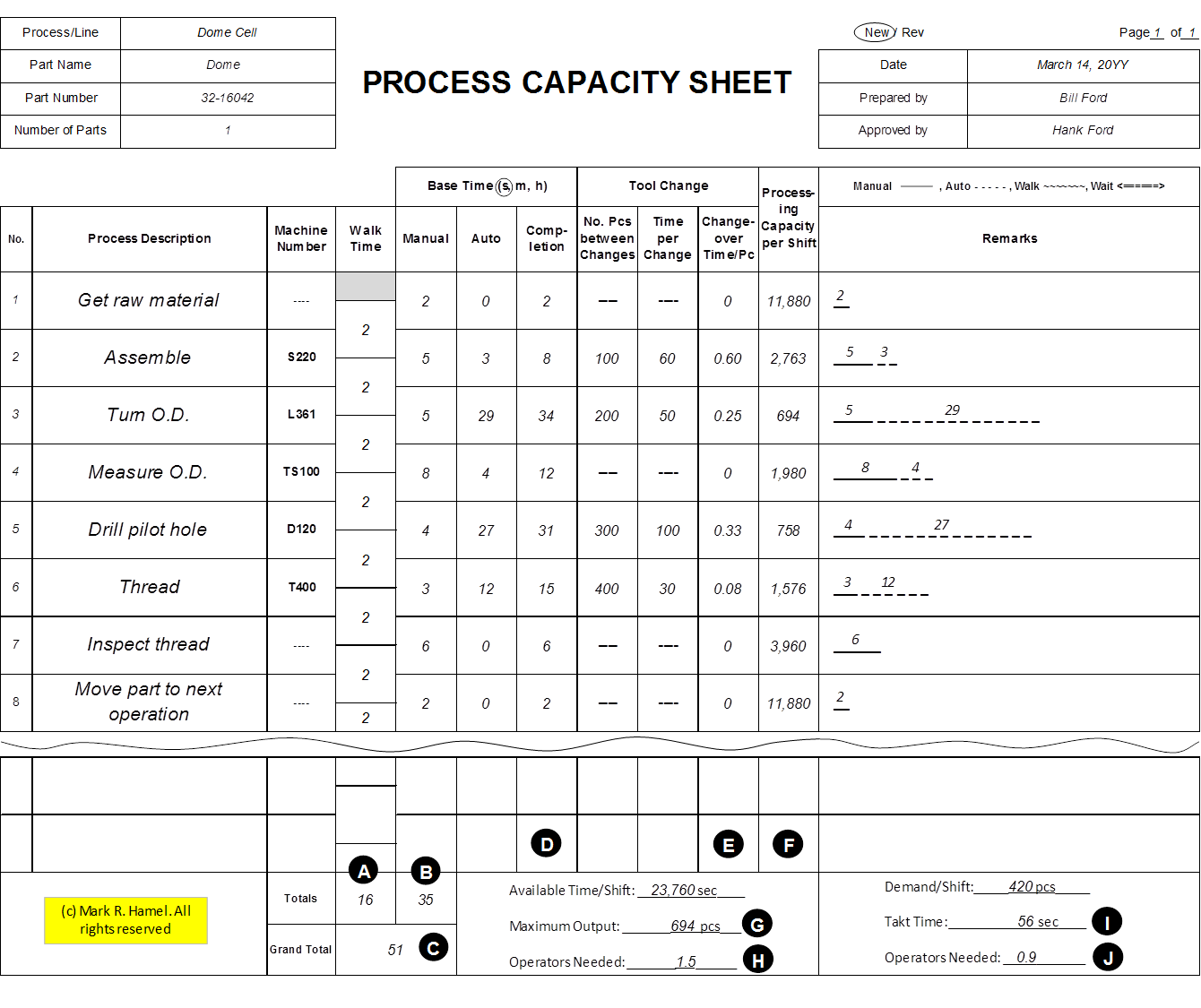

Process Capacity Sheet Math Talcott Ridge Consulting

The formula for production capacity is machine-hour capacity divided by the time it takes to produce one product. Calculate the Machine-Hour Capacity The first step in understanding production capacity is to calculate the machine-hour capacity of the factory or manufacturing plant.

Toyota Production Capacity Sheet

Formula for production capacity A factory's capacity is presented in total minutes or hours or in pieces (production per day). The formula used to calculate production capacity is: 1..

Production Capacity Definition And Example Of Production Capacity

Then, you can add the time needed to produce one item to the following production capacity formula: Production capacity is calculated as the ratio of machine hours per unit of production. 4. Figure out the production capacity for multiple products. Use the formula for production capacity for one product on each item you want to calculate the.

047 Production Capacity as a Service © Digital Excellence Navigator A European Union

1. Enter the Production Budget Enter the production budget in units. This budget is based on the revenue forecast and required inventory levels used in the financial projections template. Our production budget calculator can be used to help calculate the amount to include. Machine Capacity 2. Enter the Shift Hours

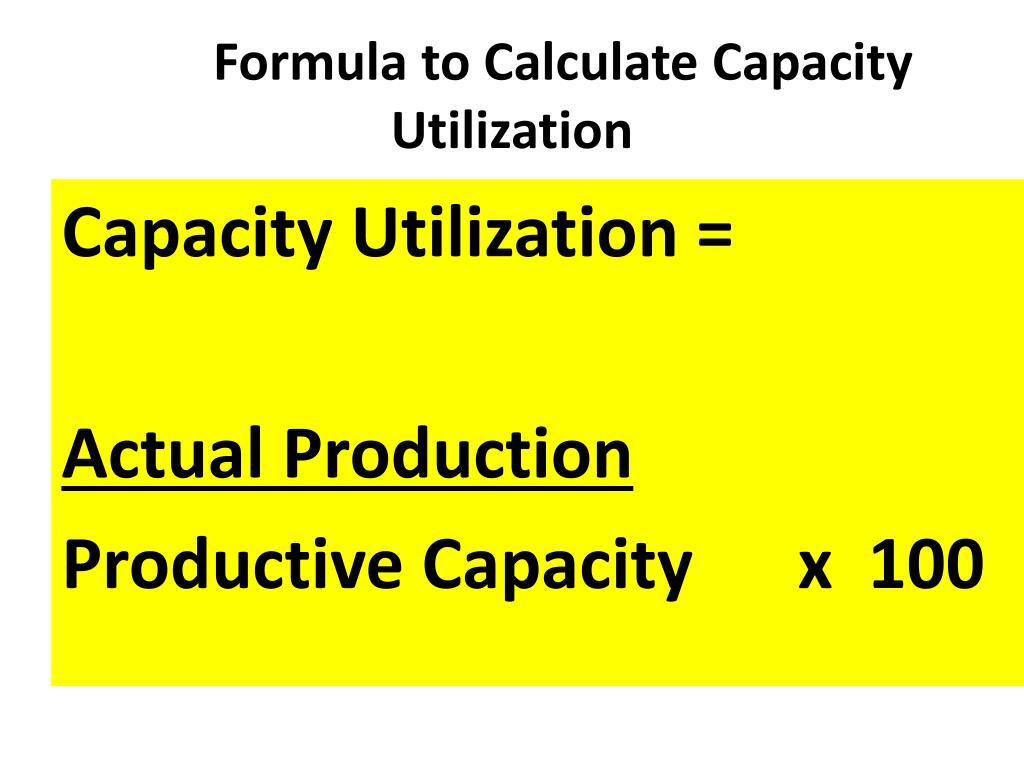

Capacity Utilization Rate Formula Calculator (Excel template)

Production capacity is the maximum possible output of a manufacturing business, measured in units of output per period. Knowing your production capacity gives you the chance to improve production planning and production scheduling, give more accurate lead times, and forecast your cash flow.

Production Capacity Shenzhen InteAuto Technology Co., Ltd

1. Determining Available Time The first step in calculating production capacity involves identifying the available production time. This encompasses the number of shifts per day, operational days per week, and any planned downtime for maintenance or retooling. The formula for available production time is:

Capacity utilisation tutor2u Business

By using a simple formula, businesses can determine how much output they can generate within a specific time period. A. Using the formula: potential production capacity = (Total potential capacity/Production time period) * 100. The formula for calculating potential production capacity in Excel is straightforward.

PPT HL OPERATIONS MANAGEMENT PRODUCTION PLANNING PowerPoint Presentation ID2735145

Production capacity is the maximum amount of output a manufacturing operation can produce. You can measure it using units produced per period of time, such as hours, days, or weeks. This factor is important because it will ultimately determine how much product you can produce in a given timeframe. Several factors can impact this, including:

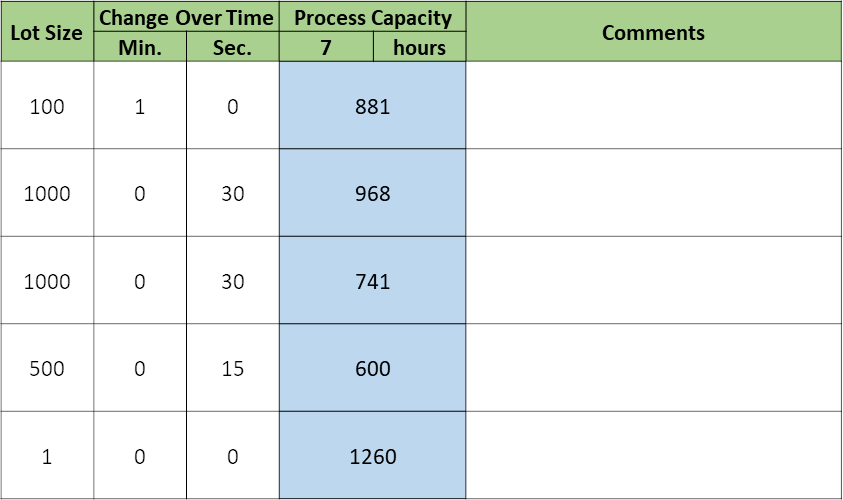

Production Capacity Sheet Processes

You can calculate the factory output rate for one product using the values from the machine-hour capacity formula. The formula is: Production Capacity = Machine-Hour Capacity (MHC) / Hours to Produce One Product. After calculating the production capacity of each product, you can calculate the factory output rate for multiple products as a sum.

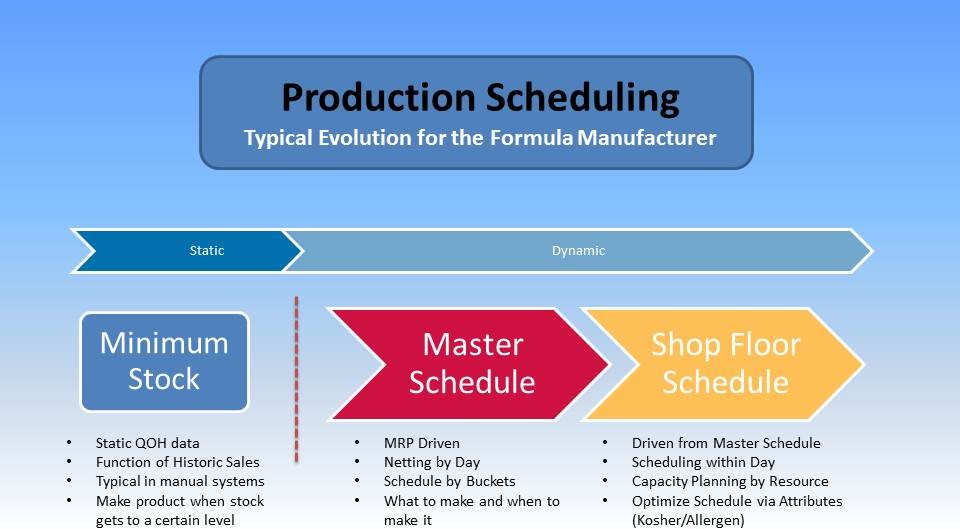

PRODUCTION SCHEDULING IHMNOTESSITE

Manufacturing capacity planning is a method makers use for calculating how much they can realistically produce on their production lines to keep up with forecasted demand. Capacity planning has to consider factors such as: Available resources Lead times Production processes Your capacity plan can be set to achieve short or long-term goals.

Utilization of the Production Capacity of GMVNs Download Scientific Diagram

The process of capacity analysis is the difference between potential capacity and the actual output a company currently achieves. By collecting production data, manufacturers can identify what process, equipment, or function needs to be changed to increase capacity. This will essentially allow manufacturers to drive greater utilization from.

A Guide To Production Capacity DataMyte

Production capacity is the output a business process can produce in a given time with finite resources under expected and normal conditions. Production Capacity is like the maximum potential of a business to produce finished goods with available budget and raw materials or inputs.