5Ton 10Ton 16Ton Overhead Crane Single Girder with Euro Design Buy Single Girder Overhead Cranes

The stand-alone program CRANEWAY calculates crane runway girders according to: EN 1993-6:2008-09 (Eurocode 3) DIN 4132:1981-02 and DIN 18800:1990-11. For the design according to EN 1993-6, you can optionally select the crane type (bridge or suspension crane). 1.

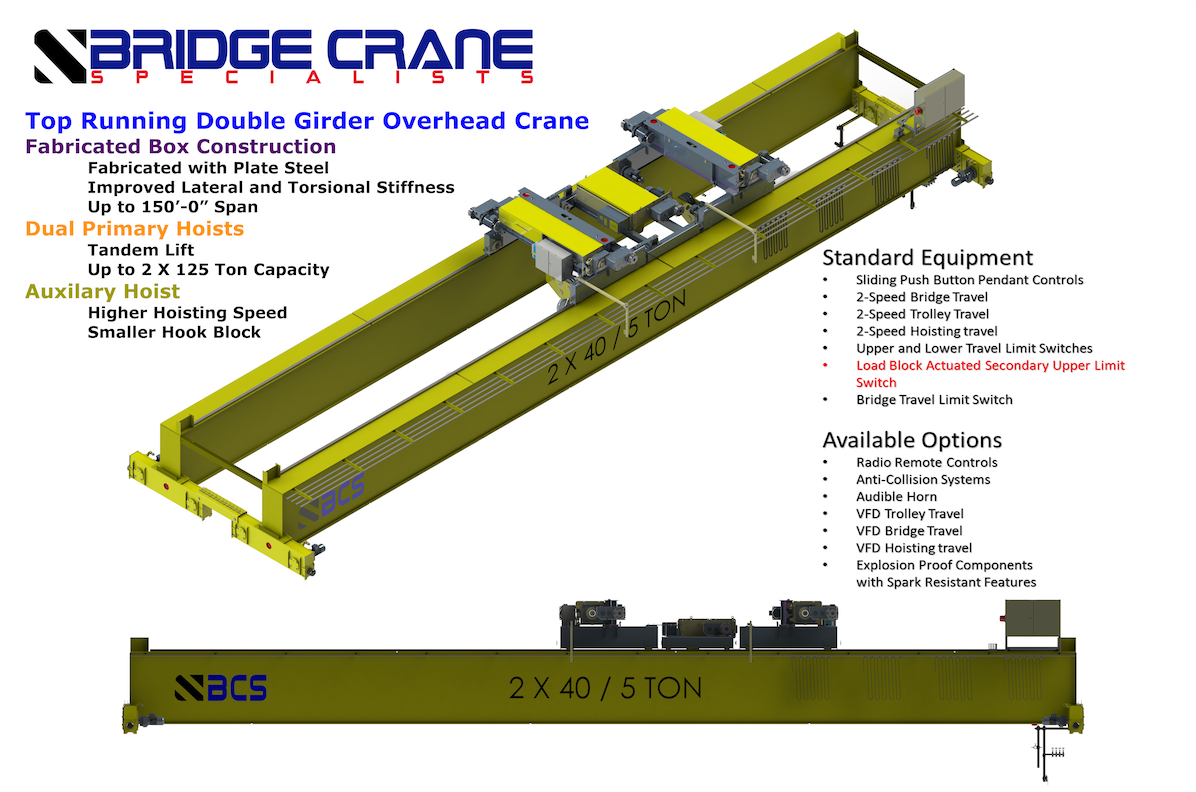

Top Running Double Girder Crane Details Bridge Crane Specialists

In 1974 SDC designed a crane girder for an industrial building with a 35T overhead crane. The girder was a standard cross section that included a rolled beam with a cap channel. The girder was designed for a lateral load equal to 10% of the lifted load per the 7 th Edition of AISC Manual of Steel Construction.

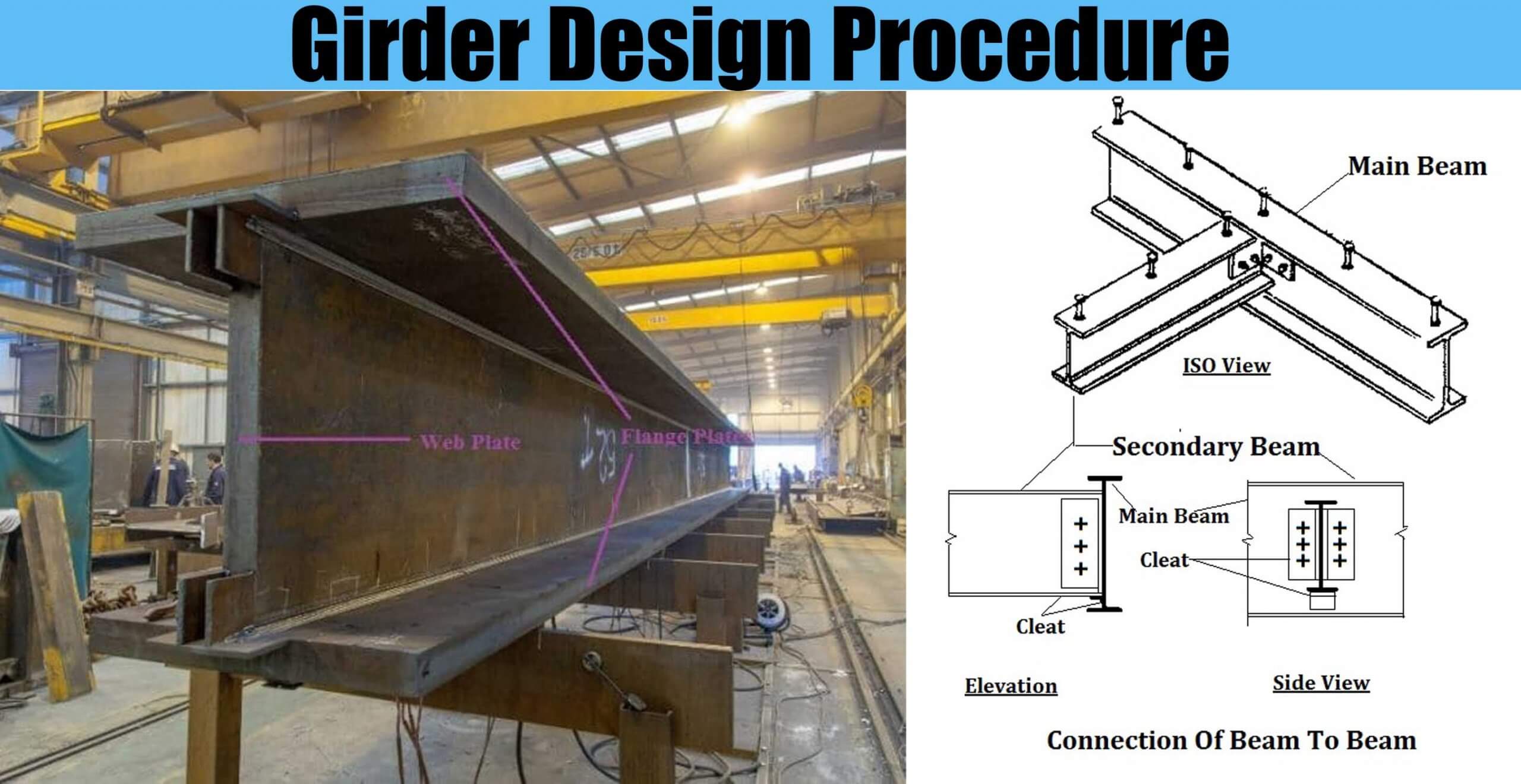

Girder Design Procedure Engineering Discoveries

Girders can be made of rolled steel or can be fabricated by welding the beams into a steel box design for added strength and rigidity. The bridge is a load-bearing beam that runs the width of the crane bay and is the primary structural component that connects the runways and moves the hoist forward and backward using a trolley.

European design 5t 150t CXTD Double Girder Overhead Crane

Advantages of a Single Girder Design: Less expensive due to a simpler trolley design, reduced freight costs, simplified and faster installation, and less material for the bridge and runway beams. Most economical option for light to medium - duty cranes. Lower loads on the building structure or foundations due to a reduced deadweight.

Double Girder Overhead Cranes Can Secure Safety And Productivity

The gantry girder is designed on the assumption that either of the horizontal forces, transverse to the rails or along the rails, act the same time as the vertical loads including the impact load. The horizontal forces act at the rail level.

Overhead Bridge Cranes Single Girder vs. Double Girder Design

Girder design of overhead cranes Overhead cranes can be segregated under two categories based on the number of cross -girders and based on the nature of running. Based on the number of cross- girders, overhead crane can be categorized as single girder and double girders.

Crane Girder Fabrications Lee Michael Industries, Inc.Lee Michael Industries, Inc.

The design of a gantry crane girder, therefore, involves the selection of a suitable and workable steel model and section to satisfy the machine (crane) requirements, loading, equipment, etc without leading to any structural or service failure. Normally, for medium-duty (say 25 to 30 t capacity) cranes, standard universal rolled I-beams are used.

Structural Design Tips for Crane Girder

The design of crane girders and supporting columns has traditionally followed allowable stress design (ASD) philosophy. With the growing acceptance of load and resistance factor design (LRFD) it has become important to review the ASD design procedures and to establish the corresponding design procedures in an LRFD format. In addition, new.

15 Years Single Girder Overhead Cranes Manufactruer ZOKE CRANE

strength, and reaction) caused by moving the crane on the crane girder, and it. means a series of analysis and design processes for designing crane girder under. common structures. This material explains the use of the crane girder analysis and design features in. midas nGen, and provides the relevant technology and verification data for this.

Gantry Girder Types, Uses, Characteristics & Design Explained Civiconcepts

Designing a crane girder according to BS5950 involves numerous steps to ensure that it can safely support the applied loads, including the weight of the crane and the lifted load, the crane movement, and the imposed wind loads. The following are the design parameters you mentioned, which are required to perform the design: Crane capacity

Gantry Girder Crane Girder Gantry Girder Design Example Types Of Gantry Cranes Gantry

Chapter 1 Chapter 2 Who We Are Contact Us New AISC Crane Girder Code Requirements Since AIST Technical Report 13 was issued in 2003, the American National Standards Institute /American Institute of Steel Construction (ANSI/AISC) 360-10 steel design code has been revised several times.

Demag VType Girder Innovating the Crane Space Demag Cranes

The uses of the gantry girder are as follows: a. To know the behavior of gantry girders. b. To determine the various loads working on the gantry girder. c. To determine the maximum bending moment and maximum shear force presence in the girders. d. Select the right cross-sections for gantry girders.

FEM Standard Double Girder Gantry Cranes Manufacturer DFHOIST

The analysis and design of the crane moving load calculate the influence of the vertical and horizontal loads (Max./Min. node displacement, Max./Min. member strength, and reaction) caused by moving the crane on the crane girder, and it means a series of analyses and design processes for designing crane girder under common structures.

L Type Gantry Cranes Manufacturer WHCRANE

Liftech News. Liftech Consultants Inc. is a leading structural, mechanical, and electrical engineering firm with over 50 years of experience providing professional engineering services and project management services for cranes, wharves, floats, buildings, heavy lift systems, and other specialized systems. Our expertise includes the design of.

Overhead Crane DesignBuild Company Now Offers InHouse Construction of Box Girder Beams Lift

Gantry Girder Design The design of the gantry girder is a trial and error procedure. In the design, it is assumed that Design of Gantry Girder Lateral load is resisted entirely by the compression flange with plates, channels, etc. The vertical load is resisted by the entire beam. Design Steps 1.

Hoosier Crane Box Girder Cranes

What are the options? Looking back at the BS 5950 examples in the SCI library, most are mono-symmetric with a channel welded to the top flange. An example with a plain plate welded to the top flange is presented in early editions of the 'Red Book'2.